Research Overview

Multi-physics topology optimization

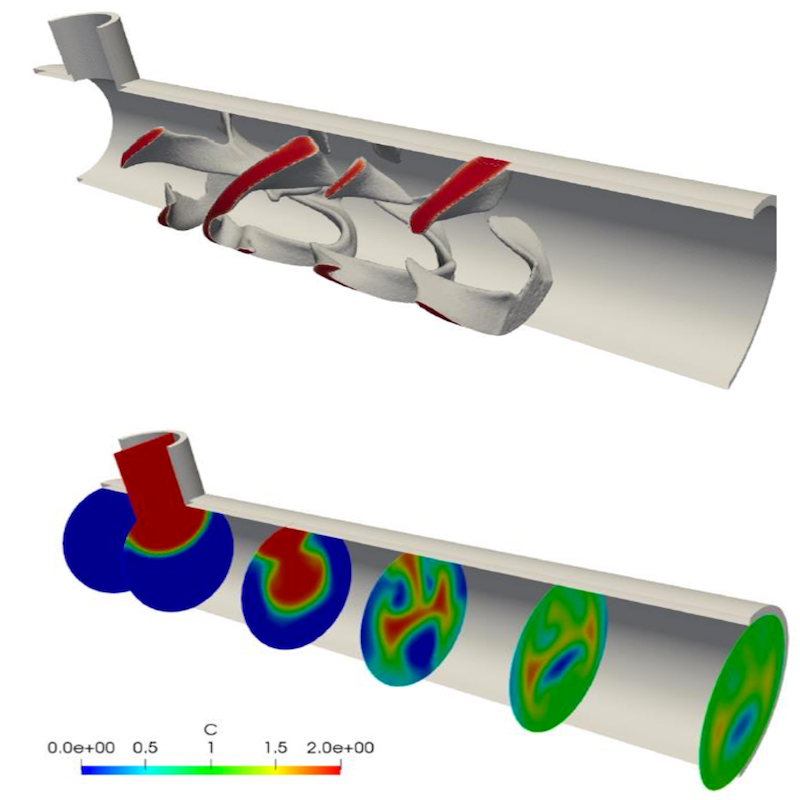

We study density-based multi-physics topology optimization. We aim to develop methods to find optimal distribution of materials to improve performances under governing physics and technological/fabrication constraints. The material distribution is parameterized by a pseudo-density profile. The analysis is based on the finite element method or the finite volume method through either our in-house analysis code, open source code such as FEniCS and OpenFOAM, or commercial software such as COMSOL. Our optimization runs in various computing platform, from desktop PCs to national supercomputers of over 2,000 CPUs. We have published our topology optimization work for a variety of multi-physics problems, including fluid-based conjugate heat transfer and mass transfer, thermophotonics, and thermoelastic problems.

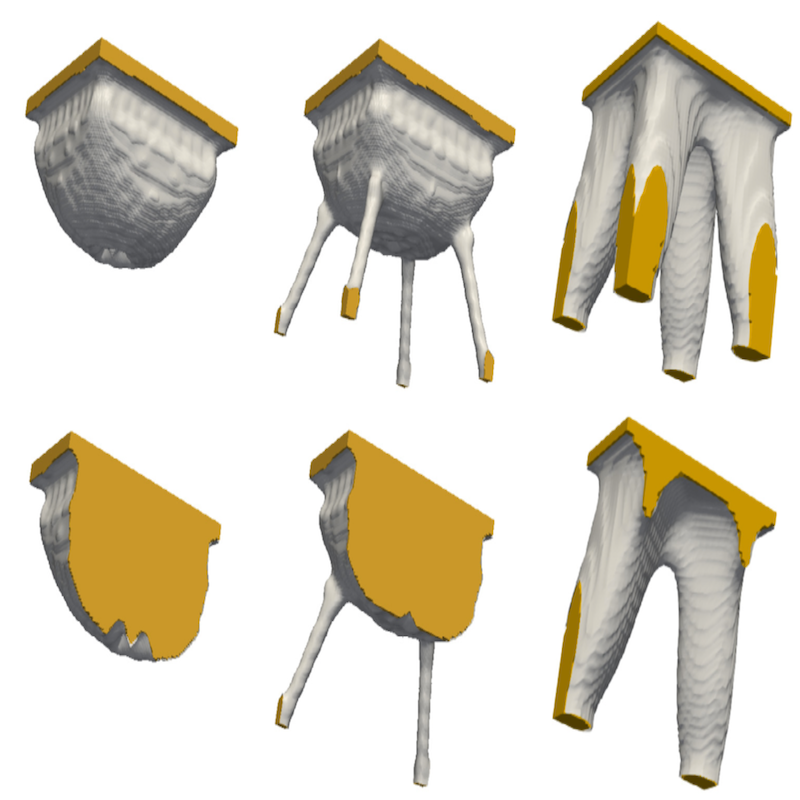

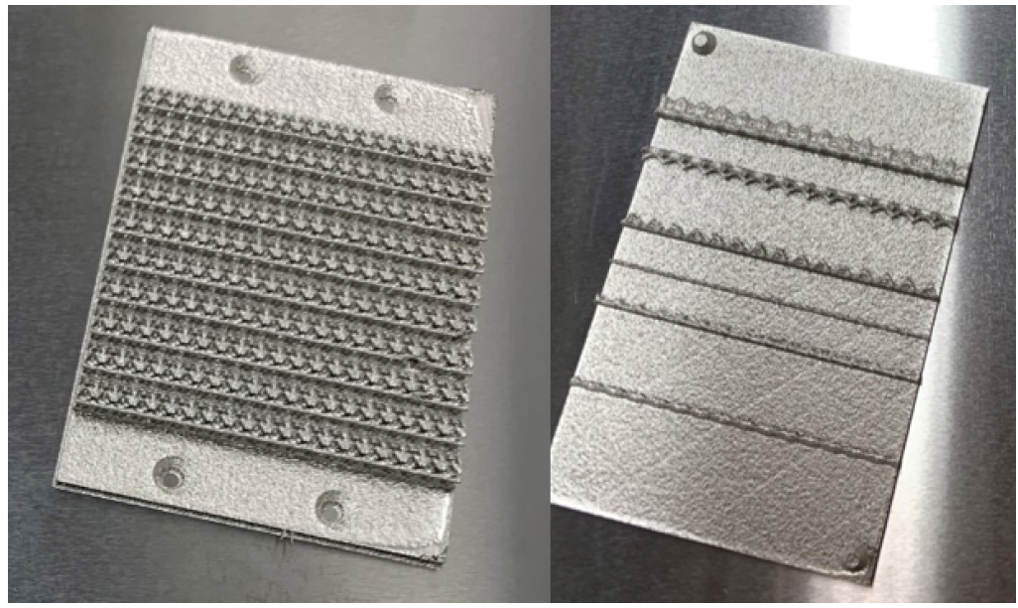

We have successfully applied topology optimization and additive manufacturing on a variety of thermal components and systems such as heat sinks, heat exchangers, and phase-change materials based latent heat energy storage systems.

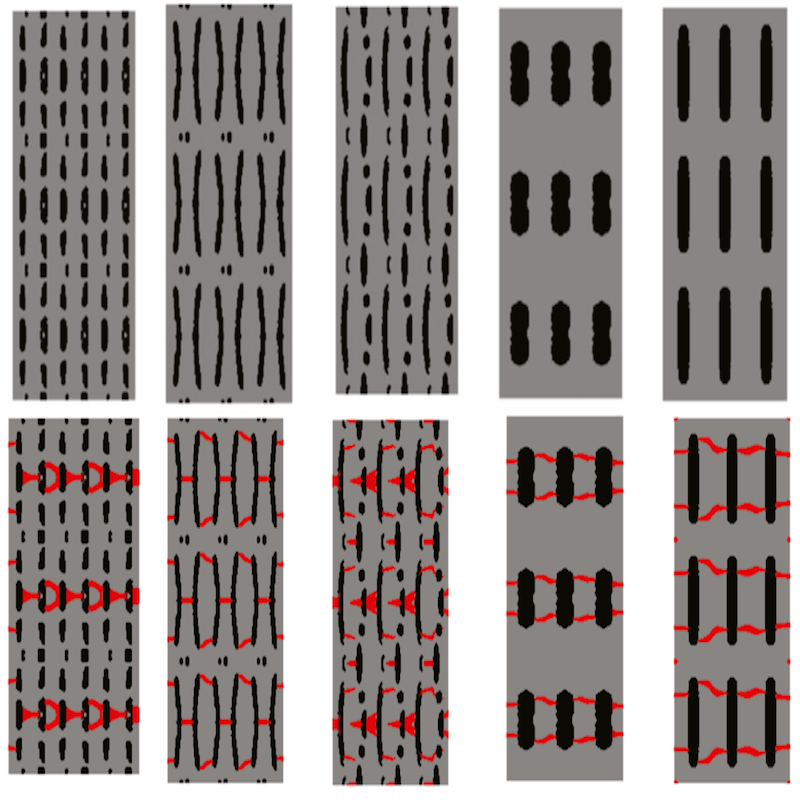

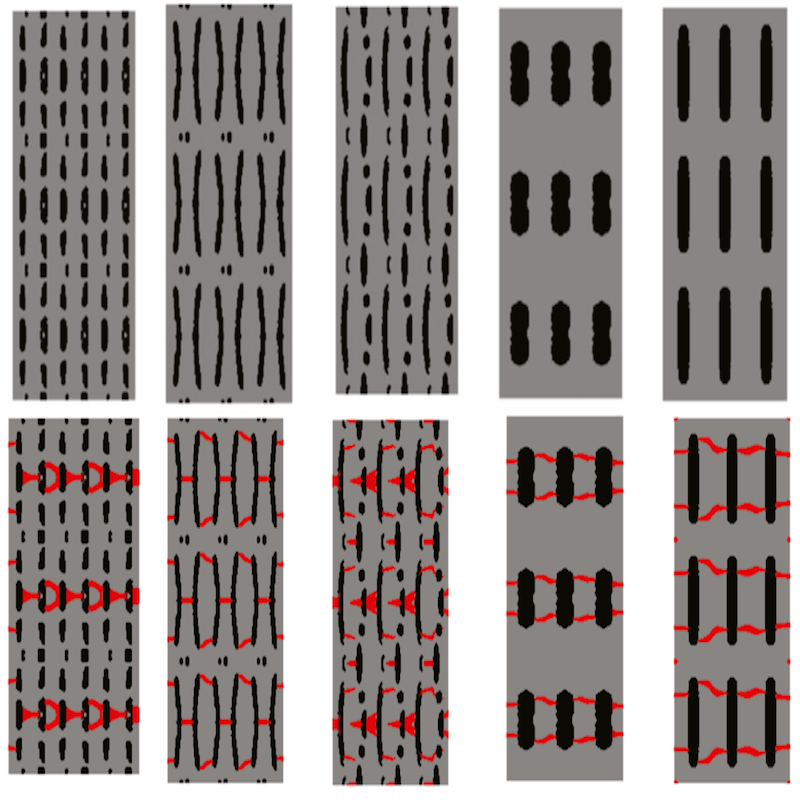

Topological evolution of a heat sink during optimization

Topologically optimized additively manufactured heat sinks (printed at Prof. Dan Thoma’s lab)

Exploded view of an optimized heat sink

Sicheng’s talk on TO of heat sinks at Topopt Webinar (Feb 23, 2021)

https://www.youtube.com/live/wZ6EVxlYHrY?si=WBCoYtkmOJTqLvzM

Design for Additive Manufacturing

We are interested in developing computer methods and mathematical formulations to account for manufacturability constraints during topology optimization so that the optimized designs can be manufactured through either additive manufacturing or subtractive machining.

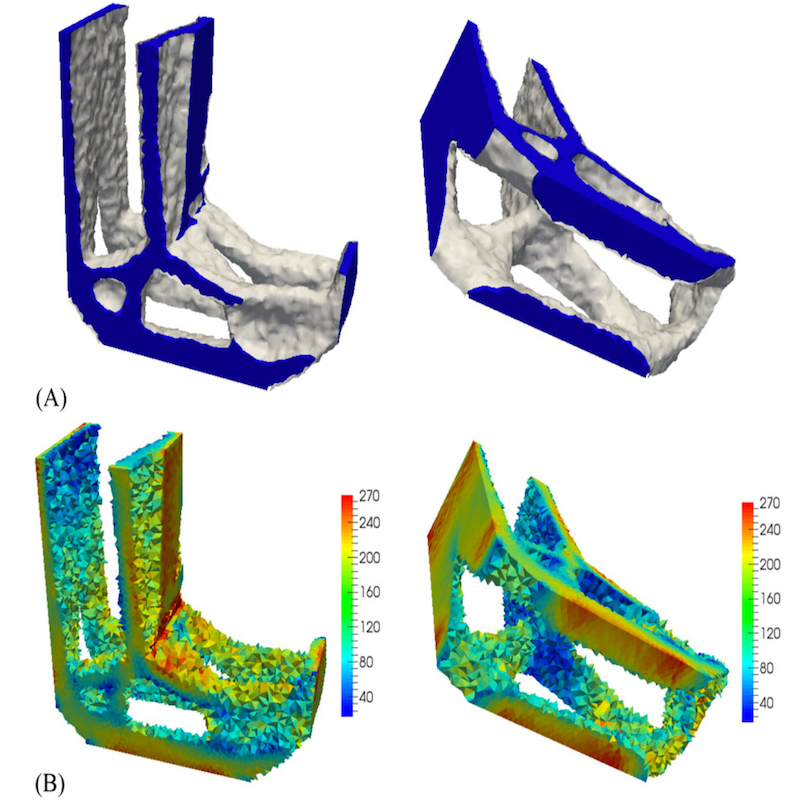

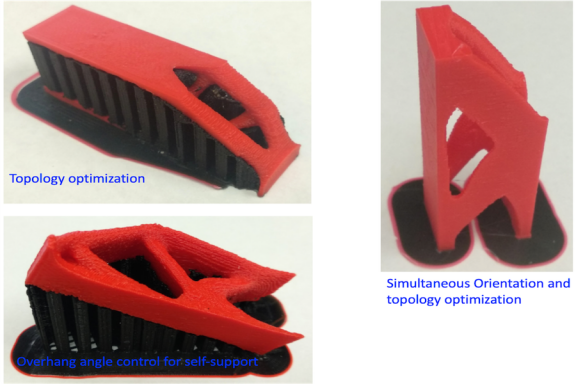

Support-free designs for additive manufacturing

The overhang angle and undercut area are controlled through a new formulation: projected undercut perimeter, in topology optimization. The resulting part has been printed with Fused Deposition Modeling without support.

Simultaneous optimization of build orientation and topology

Simultaneous optimization of build orientation and topology leads to self-supporting designs that have better performance than those with optimization under fixed orientations.

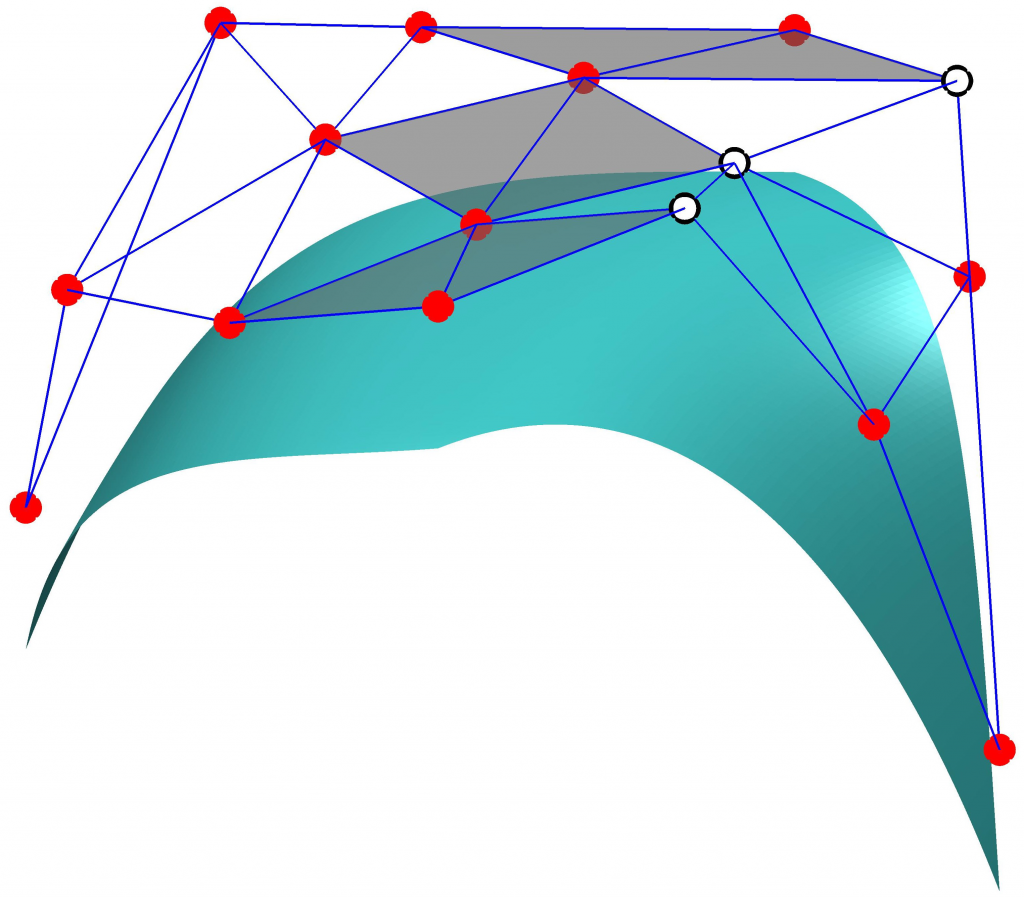

Isogeometric analysis and shape optimization

We are creating a new method for integrating CAD and finite element analysis and it is based on rational triangular Bezier elements. It has the advantages of enabling automatic parameterization, ease of local refinement, and being applicable to geometry of complex topology.

We have also developed a smooth-refine-smooth procedure to achieve optimal convergence with Cr smooth triangular elements.

This method has been used in shape optimization and analysis of various problems, including higher-order PDEs such as Kirchhoff–Love shell and Cahn-Hilliard phase-field model.